Ways to Increase Accuracy with Digital Measurements

What Are Digital Measurements?

Digital measurements are a type of measurement that uses digital technology to capture and record data. This method is used in various industries, including manufacturing, construction, engineering, and many others. Digital measurements work by converting an analog signal into a digital format that can be easily read and analyzed by computer systems.

How Do Digital Measurements Work?

Digital measurements work by converting analog signals into digital information that can be easily recorded and analyzed. The process involves sampling the analog signal at regular intervals using an analog-to-digital converter (ADC). The ADC converts the continuous analog signal into discrete digital values, which are then processed by a microcontroller or computer. This processing allows for advanced analysis and manipulation of the data.

Benefits of Using Digital Measurements

Digital measurements offer several advantages over traditional methods, including increased accuracy and precision, automatic recording of data, and reduced human error. They also allow for real-time monitoring of processes and systems. Digital measurement tools provide convenience, speed, and non-invasiveness, making them an essential part of modern-day industry operations.

Common Challenges in Achieving Accurate Digital Measurements

Despite the benefits of digital measurements, there are common challenges that can hinder accurate results. Calibration issues, data errors, and device limitations are some of the obstacles that need to be addressed to achieve accuracy with digital measurement tools. Regular calibration, proper handling and storage of tools, and selecting the right tool for each job can help mitigate these challenges.

Key Techniques to Increase Accuracy

To maximize accuracy with digital measurements, several key techniques can be implemented. Regular calibration of tools is crucial to ensure they are functioning properly and providing accurate measurements. Using the right tool for the job is essential, considering factors such as precision, resolution, and speed. Proper training and skills development among users also play a significant role in achieving accurate digital measurements.

Overview of Digital Measurement Tools

Digital measurement tools come in various forms, such as digital calipers, micrometers, angle finders, and laser distance meters. These tools offer high accuracy levels and convenience with features like Bluetooth connectivity and data storage capabilities. They have revolutionized the way measurements are taken, providing efficient and accurate results for analysis and further processing.

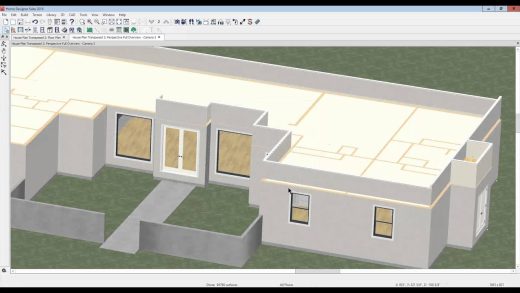

Advanced 3D Scanning Technology

Advanced 3D scanning technology is a powerful tool that captures precise geometric data from physical objects and converts them into highly accurate digital models. It allows for non-destructive testing, provides intricate details, and finds applications in various industries, from manufacturing to medicine and archaeology.

Maximizing Accuracy in Specific Applications

To maximize accuracy in specific applications, different techniques and tools can be employed. For geometric measurements, 3D scanning technology reduces errors caused by manual measurements. Laser micrometers and coordinate measuring machines (CMMs) provide precise results for thickness, depth, and dimensional metrology measurements. Optical comparators are useful for quality control inspections. Choosing the right tool for the job, along with proper training, contributes to accuracy.

Understanding Errors in Digital Measurements

Errors can occur in digital measurements due to environmental factors, instrument limitations, data analysis, and user error. Minimizing errors involves measuring in controlled environments, maintaining and calibrating instruments regularly, ensuring proper data entry and processing, and providing adequate training to users.

How to Choose the Right Digital Measurement Tools

Choosing the right digital measurement tool requires considering factors such as the type of measurement needed, required accuracy levels, ease of use, durability, and additional features. Selecting the appropriate tool for the specific application ensures accurate and reliable measurements.

Software Solutions for Digital Measurement Accuracy

Software solutions enhance digital measurement accuracy through advanced algorithms and data processing techniques. They offer real-time feedback, improve efficiency, and provide data visualization and reporting capabilities. Software solutions should be used in conjunction with proper training and calibration for optimal results.

By following these techniques and utilizing the advancements in digital measurement technology, accurate and precise measurements can be achieved across various industries.